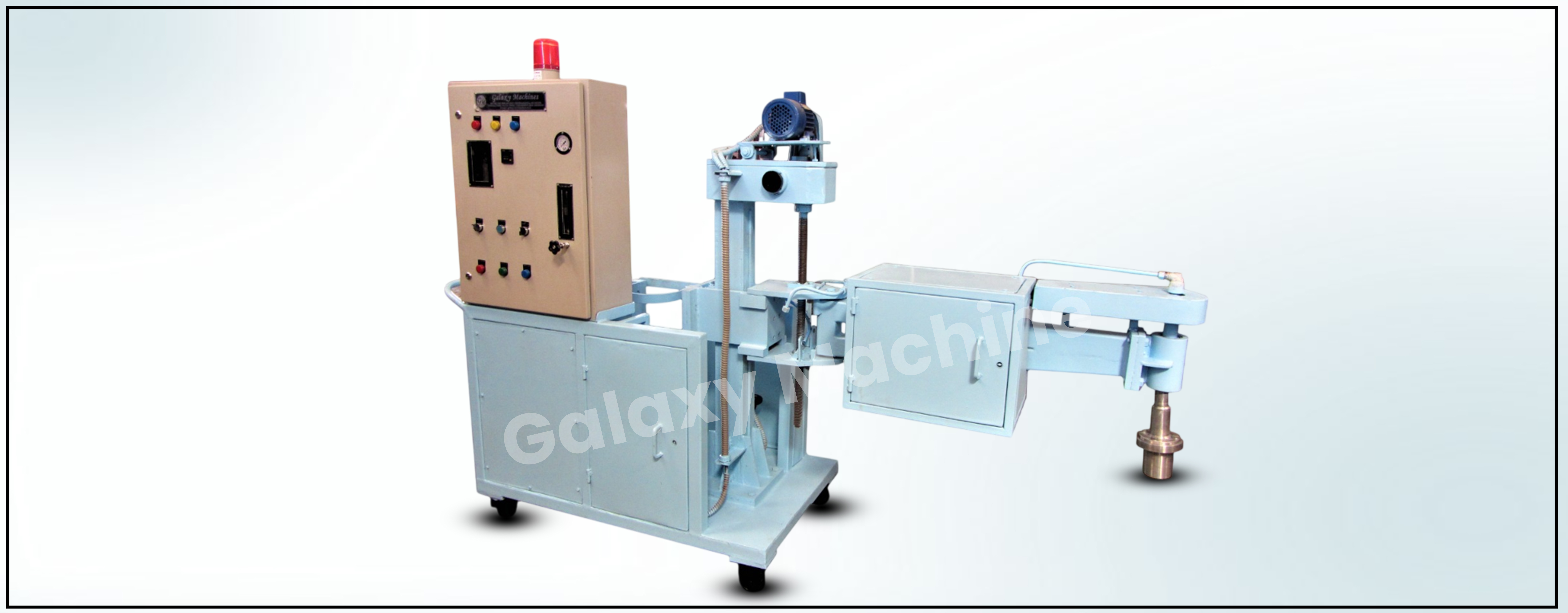

De-gassing machines are used to remove impurities from molten aluminium in furnaces. The machine contains a rotor mechanism attached to a stainless steel sleeve and a graphite rod. The graphite rod is inserted into the molten aluminium. Nitrogen gas is passed through the sleeve and it come out to the molten metal through graphite rod. The nitrogen gas removes all the impurities and sludge is formed on the top of molten metal. This sludge is removed and the cleaned aluminium can now be used for casting. Nitrogen flow meter with needle valve, solenoid valve to control movement, regulator and interlock for pressure of nitrogen flow are provided. A.C. drive or step pulley with three speeds can be provided for speed variation if required. Control panel, hooter, indication lamp, limit switches for both up and down position, rpm indication and counter, timer for rotation are provided. One set of graphite rotor and sleeve is proved free of cost along with the machine. Both automatic and manual models are available.

Trolley with parking brake and arm rotation through 180o with locking arrangement is provided. Whole assembly is mounted on trolley and can be moved from one furnace to another on wheels.

Machine is mounted on one base plate which is fixed on concrete pillar near furnace. Arm rotates through 180o.

Whole assembly is mounted on one structure which moves on monorails. This machine can be moved from one furnace to another on monorail for de-gassing purpose.